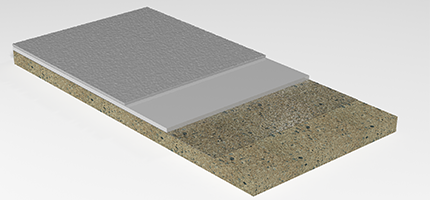

Vulkem® 350NF/351NF is a composite waterproofing system comprised of tough-curing liquid polyurethane. It cures to form a rubber membrane surface that provides a lasting and easy-to-clean coating. Textured surfaces for pedestrian traffic will use an aggregate-laden top membrane to aid in wear and slip resistance. Vulkem 350NF/351NF may be used to apply a seamless, monolithic waterproof membrane to concrete, well-anchored AC plywood, and primed metal surfaces.

Try our new building visualizer tool and see your project come to life.

Prior to proceeding, existing moisture should be removed and the surface should be wiped with a compliant, non-alcohol based solvent or other approved cleaner. Contact Technical Services for recommendations. Allow the solvent to flash dry. Prime using either Vulkem 191 Primer or TREMprime Multi-Surface Urethane Primer. Primer selection is driven by local compliance and regulations and secondarily by contractor preference. Apply primer at recommended coverage rates found on the primer selection guide on the website. Dry times will vary by primer and will also be affected by temperature and humidity conditions. Vulkem 191 Primer should dry to a "tack" and Tremco Multi-Surface Urethane Primer should be allowed to fully dry prior to proceeding with application of the subsequent Vulkem coating. Please consult Tremco’s Technical Services team

Vulkem Traffic Coatings should be applied to dry, frost-free substrates having a temperature of 40 °F (5 °C) and rising. For specific project recommendations, please contact Technical Services or your local sales representative.

Wood must be a minimum 5/8” (16mm) thickness exterior grade plywood laid with the "A" side up and securely fastened to meet local uplift and other building code requirements. A consistent 1/16" joint should be provided between adjacent panels. See Tremco details for appropriate detailing of joints prior to application of coating. Reference system specific product data sheets for priming requirements and other application guidelines. Metal substrates must be restored to a clean, bright finish free of oxidation, previously applied coatings and other residue or contaminants. Metal substrates should be primed with Tremco’s TREMprime Non-Porous Primer. For priming coverage rates and application techniques, please call Technical Service.

Vulkem Coatings should not be applied to concrete that has had curing agents, sealers or water repellants applied. All concrete surfaces must be clean, sound and free of all contamination. Chemical and/or mechanical surface preparation may be required. Contact Tremco Technical Services or your local sales representative for project specific requirements.

The service temperature range for traffic coatings is -40°F to 185°F (-40°C to 85°C).