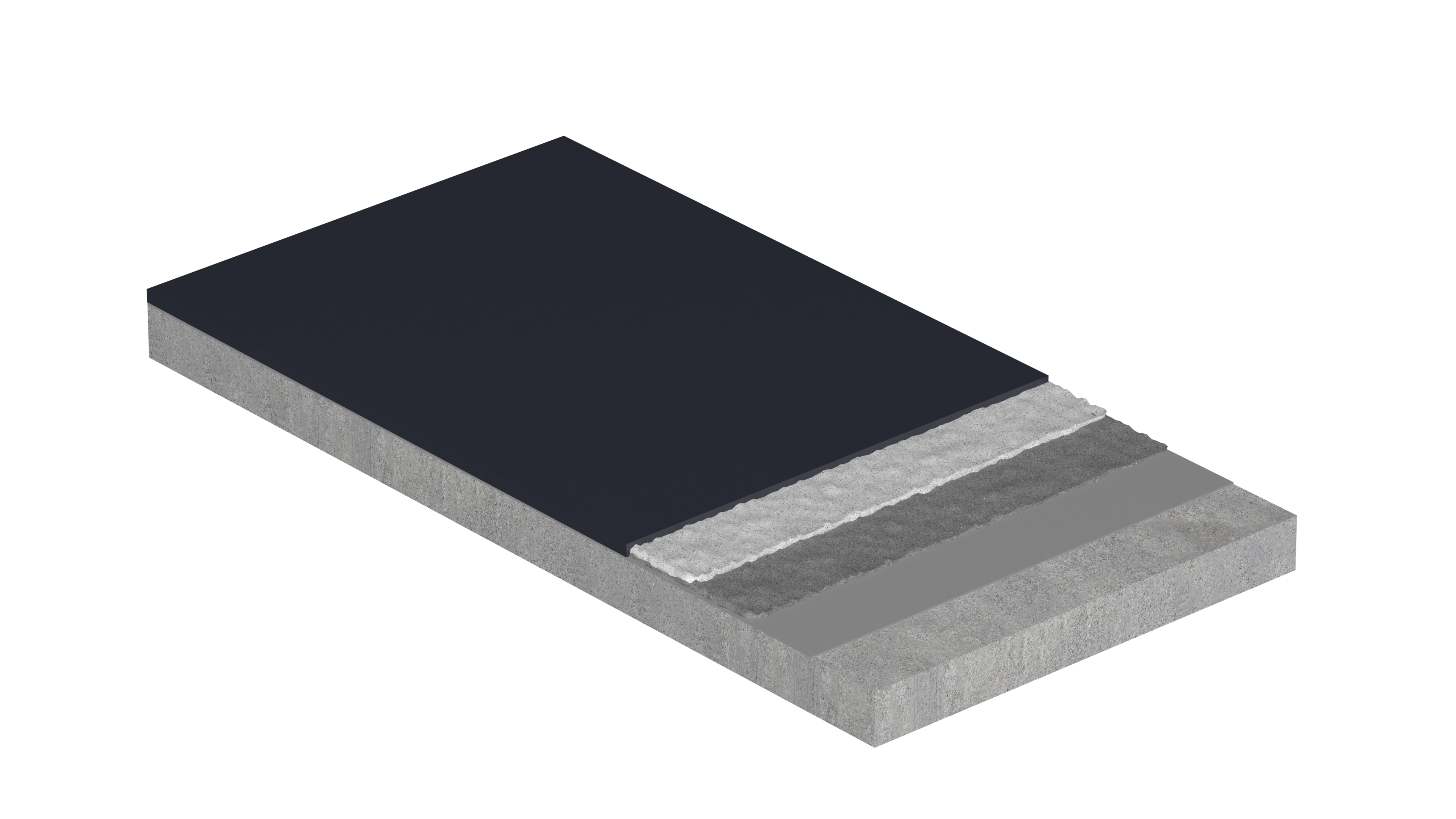

Vulkem® 350FC/EWS Hybrid Vehicular Traffic Deck Coating System is designed to have a tenacious bond to concrete and extreme abrasion resistance. Vulkem Extreme Wearing System (EWS) is a waterproof traffic deck coating system that utilizes polyurethane-methacrylate (PUMA) technology. Vulkem 350FC/EWS Hybrid Vehicular System is composed of two layers of 2 component fast cure crack bridging urethane base coat (Vulkem 350FC), an intermediate wear coat (Tremco PUMA WC) and a topcoat (Tremco PUMA TC)

Vulkem® 350FC/EWS Hybrid is a cold applied traffic deck coating system designed for waterproofing concrete slabs and protecting occupied areas underneath from water damage. The system will protect the concrete from the damaging effects of water, deicing salts, chemicals, gasoline, oils and anti-freeze.

No. Traditional constructions solvents such as xylene, mineral spirits, acetone, isopropyl alcohol, etc cannot be used with PUMA Technology. All cleaning of tools and coating must be done with Tremco PUMA Cleaner.

No. Tremco PUMA components contain both polyurethane methacrylate and methyl methacrylate. While these ingredients carry a distinct odor, neither are harmful. In fact, the chemical makeup is almost identical to acrylics used in nail salons.

PUMA Technology can be applied down to 20 °F/ -7 °C.

Each layer of all PUMA technology systems cure in 30-45 minutes and the next coat can be applied at that time. In fact, they can be opened up to traffic one hour after installation is complete.

Minimum recommended cure times are as follows: Vulkem 350 with 950NF or 951NF Pedestrian Deck Coating is 12 hours. Vulkem 350/351 Pedestrian Deck Coating and the Vulkem 350/950NF/951NF Vehicular Traffic System are 24 hours. The Vulkem 350/346/346 Vehicular Traffic System is 72 hours. Please note that these are minimum recommended cure times and site-specific conditions, weather and temperature all impact cure rate and interlaminary adhesion development. Contact your local sales representative for project specific recommendations.

Prior to proceeding, existing moisture should be removed and the surface should be wiped with a compliant, non-alcohol based solvent or other approved cleaner. Contact Technical Services for recommendations. Allow the solvent to flash dry. Prime using either Vulkem 191 Primer or TREMprime Multi-Surface Urethane Primer. Primer selection is driven by local compliance and regulations and secondarily by contractor preference. Apply primer at recommended coverage rates found on the primer selection guide on the website. Dry times will vary by primer and will also be affected by temperature and humidity conditions. Vulkem 191 Primer should dry to a "tack" and Tremco Multi-Surface Urethane Primer should be allowed to fully dry prior to proceeding with application of the subsequent Vulkem coating. Please consult Tremco’s Technical Services team.

Vulkem Traffic Coatings should be applied to dry, frost-free substrates having a temperature of 40 °F (5 °C) and rising. For specific project recommendations, please contact Technical Services or your local sales representative.

Concrete should be water-cured and in place a minimum of 14 days, and rubber mat tested, thermal imaged or otherwise evaluated for maximum allowable moisture prior to the application of Vulkem Traffic Coatings. Contact Technical Services for preferred or approved gauges and evaluation methods.

Vulkem Coatings should not be applied to concrete that has had curing agents, sealers or water repellants applied. All concrete surfaces must be clean, sound and free of all contamination. Chemical and/or mechanical surface preparation may be required. Contact Tremco Technical Services or your local sales representative for project specific requirements.

The service temperature range for traffic coatings is -40°F to 185°F (-40°C to 85°C).